The manufacturing processes for MCU (Microcontroller Unit) evaluation boards have evolved significantly over the years to meet the increasing demands for smaller, faster, and more efficient devices. In this article, we will explore the latest manufacturing processes used in the production of MCU evaluation boards.

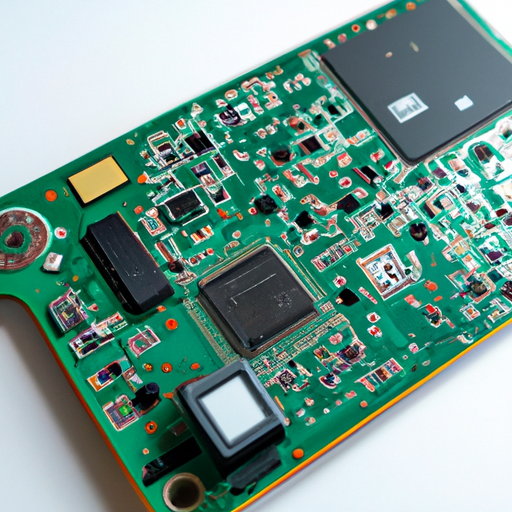

1. Surface Mount Technology (SMT): Surface mount technology is a widely used manufacturing process for MCU evaluation boards. In this process, electronic components are mounted directly onto the surface of the PCB (Printed Circuit Board) using solder paste and a reflow oven. This process allows for smaller components to be used, resulting in a more compact and lightweight board.

2. Automated Assembly: Automated assembly is another key manufacturing process for MCU evaluation boards. This process involves the use of robotic machines to place and solder components onto the PCB. Automated assembly not only speeds up the production process but also ensures greater accuracy and consistency in component placement.

3. High-Density Interconnect (HDI) Technology: HDI technology is a manufacturing process that allows for the creation of complex PCB designs with high component density. This technology enables the use of multiple layers of copper traces and vias, resulting in a more compact and efficient board layout. HDI technology is particularly useful for MCU evaluation boards that require a high level of integration and functionality.

4. Advanced Packaging Techniques: Advanced packaging techniques, such as System-in-Package (SiP) and Multi-Chip Modules (MCM), are increasingly being used in the production of MCU evaluation boards. These techniques involve the integration of multiple components, such as microcontrollers, memory, and sensors, into a single package. This results in a more compact and efficient board design, with improved performance and reliability.

5. 3D Printing: 3D printing is a relatively new manufacturing process that is starting to be used in the production of MCU evaluation boards. 3D printing allows for the rapid prototyping and production of custom-designed PCBs, with complex shapes and features that would be difficult or impossible to achieve using traditional manufacturing methods. 3D printing is particularly useful for small-batch production runs and for creating highly customized boards for specific applications.

6. Environmental Considerations: In addition to the manufacturing processes themselves, there is also a growing emphasis on environmental considerations in the production of MCU evaluation boards. Manufacturers are increasingly using lead-free solder and RoHS-compliant materials to reduce the environmental impact of their products. Additionally, efforts are being made to reduce waste and energy consumption in the manufacturing process, through the use of efficient production techniques and recycling programs.

In conclusion, the manufacturing processes for MCU evaluation boards have evolved significantly in recent years, with a focus on smaller, faster, and more efficient devices. Surface mount technology, automated assembly, HDI technology, advanced packaging techniques, 3D printing, and environmental considerations are all key factors in the production of high-quality MCU evaluation boards. By staying up-to-date with the latest manufacturing processes and technologies, manufacturers can continue to meet the growing demands for advanced MCU evaluation boards in a rapidly evolving market.

The manufacturing processes for MCU (Microcontroller Unit) evaluation boards have evolved significantly over the years to meet the increasing demands for smaller, faster, and more efficient devices. In this article, we will explore the latest manufacturing processes used in the production of MCU evaluation boards.

1. Surface Mount Technology (SMT): Surface mount technology is a widely used manufacturing process for MCU evaluation boards. In this process, electronic components are mounted directly onto the surface of the PCB (Printed Circuit Board) using solder paste and a reflow oven. This process allows for smaller components to be used, resulting in a more compact and lightweight board.

2. Automated Assembly: Automated assembly is another key manufacturing process for MCU evaluation boards. This process involves the use of robotic machines to place and solder components onto the PCB. Automated assembly not only speeds up the production process but also ensures greater accuracy and consistency in component placement.

3. High-Density Interconnect (HDI) Technology: HDI technology is a manufacturing process that allows for the creation of complex PCB designs with high component density. This technology enables the use of multiple layers of copper traces and vias, resulting in a more compact and efficient board layout. HDI technology is particularly useful for MCU evaluation boards that require a high level of integration and functionality.

4. Advanced Packaging Techniques: Advanced packaging techniques, such as System-in-Package (SiP) and Multi-Chip Modules (MCM), are increasingly being used in the production of MCU evaluation boards. These techniques involve the integration of multiple components, such as microcontrollers, memory, and sensors, into a single package. This results in a more compact and efficient board design, with improved performance and reliability.

5. 3D Printing: 3D printing is a relatively new manufacturing process that is starting to be used in the production of MCU evaluation boards. 3D printing allows for the rapid prototyping and production of custom-designed PCBs, with complex shapes and features that would be difficult or impossible to achieve using traditional manufacturing methods. 3D printing is particularly useful for small-batch production runs and for creating highly customized boards for specific applications.

6. Environmental Considerations: In addition to the manufacturing processes themselves, there is also a growing emphasis on environmental considerations in the production of MCU evaluation boards. Manufacturers are increasingly using lead-free solder and RoHS-compliant materials to reduce the environmental impact of their products. Additionally, efforts are being made to reduce waste and energy consumption in the manufacturing process, through the use of efficient production techniques and recycling programs.

In conclusion, the manufacturing processes for MCU evaluation boards have evolved significantly in recent years, with a focus on smaller, faster, and more efficient devices. Surface mount technology, automated assembly, HDI technology, advanced packaging techniques, 3D printing, and environmental considerations are all key factors in the production of high-quality MCU evaluation boards. By staying up-to-date with the latest manufacturing processes and technologies, manufacturers can continue to meet the growing demands for advanced MCU evaluation boards in a rapidly evolving market.