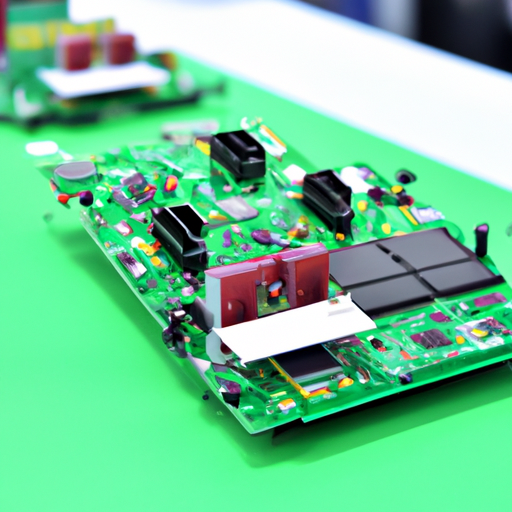

Linear voltage regulator boards are essential components in many electronic devices, providing a stable output voltage despite fluctuations in input voltage or load. The production process for these boards involves several key steps to ensure quality and reliability. In this article, we will explore the mainstream linear voltage regulator board production process in detail.

1. Design and Planning

The first step in the production process is the design and planning phase. This involves determining the specifications and requirements for the linear voltage regulator board, including the desired output voltage, current capacity, input voltage range, and other key parameters. The design team will also consider factors such as size, cost, and efficiency in developing the board layout and circuitry.

Once the design is finalized, a production plan is created that outlines the materials, components, and equipment needed for manufacturing. This plan will also include a timeline for each step of the production process, from sourcing components to final assembly and testing.

2. Component Sourcing

The next step in the production process is sourcing the components needed to build the linear voltage regulator board. This includes electronic components such as resistors, capacitors, diodes, transistors, and the voltage regulator IC itself. These components are typically sourced from suppliers who specialize in electronic components and have a reputation for quality and reliability.

In addition to electronic components, the production team will also need to source materials for the board itself, such as PCBs (printed circuit boards), solder, and other materials used in assembly. These materials must meet the specifications outlined in the design phase to ensure the board functions correctly.

3. PCB Fabrication

Once the components are sourced, the next step is to fabricate the PCBs that will serve as the foundation for the linear voltage regulator board. PCB fabrication involves several steps, including designing the PCB layout, printing the circuit pattern onto the board, etching away excess copper, and drilling holes for components.

PCB fabrication is typically outsourced to specialized manufacturers who have the equipment and expertise to produce high-quality boards. The production team will work closely with the PCB manufacturer to ensure that the boards meet the design specifications and quality standards required for the linear voltage regulator board.

4. Component Assembly

With the PCBs fabricated, the next step is to assemble the components onto the board. This process involves placing the electronic components onto the PCB, soldering them in place, and trimming excess leads. Component assembly is a critical step in the production process, as any errors or defects in assembly can lead to malfunctions or failures in the finished board.

To ensure quality and consistency in component assembly, many manufacturers use automated assembly equipment such as pick-and-place machines and reflow ovens. These machines can quickly and accurately place components onto the PCB and solder them in place, reducing the risk of errors and improving efficiency.

5. Testing and Quality Control

Once the components are assembled onto the PCB, the next step is to test the board to ensure it functions correctly. This involves applying power to the board and measuring the output voltage, current, and other key parameters to verify that they meet the design specifications. Any boards that fail testing are identified and either repaired or discarded.

In addition to functional testing, the boards are also subjected to quality control checks to ensure they meet the required standards for reliability and durability. This may include visual inspection for defects, testing for thermal performance, and environmental testing to simulate real-world conditions.

6. Packaging and Shipping

Once the linear voltage regulator boards have passed testing and quality control checks, the final step is to package them for shipping to customers. This may involve placing the boards in anti-static bags or trays to protect them during transit, as well as labeling them with product information and specifications.

The packaged boards are then shipped to customers or distributors for use in electronic devices. Throughout the production process, manufacturers must maintain strict quality control measures to ensure that the boards meet the required standards for performance and reliability.

In conclusion, the mainstream linear voltage regulator board production process involves several key steps, from design and planning to component sourcing, PCB fabrication, component assembly, testing, and quality control. By following these steps carefully and using high-quality materials and components, manufacturers can produce linear voltage regulator boards that meet the required specifications and provide reliable performance in electronic devices.

Linear voltage regulator boards are essential components in many electronic devices, providing a stable output voltage despite fluctuations in input voltage or load. The production process for these boards involves several key steps to ensure quality and reliability. In this article, we will explore the mainstream linear voltage regulator board production process in detail.

1. Design and Planning

The first step in the production process is the design and planning phase. This involves determining the specifications and requirements for the linear voltage regulator board, including the desired output voltage, current capacity, input voltage range, and other key parameters. The design team will also consider factors such as size, cost, and efficiency in developing the board layout and circuitry.

Once the design is finalized, a production plan is created that outlines the materials, components, and equipment needed for manufacturing. This plan will also include a timeline for each step of the production process, from sourcing components to final assembly and testing.

2. Component Sourcing

The next step in the production process is sourcing the components needed to build the linear voltage regulator board. This includes electronic components such as resistors, capacitors, diodes, transistors, and the voltage regulator IC itself. These components are typically sourced from suppliers who specialize in electronic components and have a reputation for quality and reliability.

In addition to electronic components, the production team will also need to source materials for the board itself, such as PCBs (printed circuit boards), solder, and other materials used in assembly. These materials must meet the specifications outlined in the design phase to ensure the board functions correctly.

3. PCB Fabrication

Once the components are sourced, the next step is to fabricate the PCBs that will serve as the foundation for the linear voltage regulator board. PCB fabrication involves several steps, including designing the PCB layout, printing the circuit pattern onto the board, etching away excess copper, and drilling holes for components.

PCB fabrication is typically outsourced to specialized manufacturers who have the equipment and expertise to produce high-quality boards. The production team will work closely with the PCB manufacturer to ensure that the boards meet the design specifications and quality standards required for the linear voltage regulator board.

4. Component Assembly

With the PCBs fabricated, the next step is to assemble the components onto the board. This process involves placing the electronic components onto the PCB, soldering them in place, and trimming excess leads. Component assembly is a critical step in the production process, as any errors or defects in assembly can lead to malfunctions or failures in the finished board.

To ensure quality and consistency in component assembly, many manufacturers use automated assembly equipment such as pick-and-place machines and reflow ovens. These machines can quickly and accurately place components onto the PCB and solder them in place, reducing the risk of errors and improving efficiency.

5. Testing and Quality Control

Once the components are assembled onto the PCB, the next step is to test the board to ensure it functions correctly. This involves applying power to the board and measuring the output voltage, current, and other key parameters to verify that they meet the design specifications. Any boards that fail testing are identified and either repaired or discarded.

In addition to functional testing, the boards are also subjected to quality control checks to ensure they meet the required standards for reliability and durability. This may include visual inspection for defects, testing for thermal performance, and environmental testing to simulate real-world conditions.

6. Packaging and Shipping

Once the linear voltage regulator boards have passed testing and quality control checks, the final step is to package them for shipping to customers. This may involve placing the boards in anti-static bags or trays to protect them during transit, as well as labeling them with product information and specifications.

The packaged boards are then shipped to customers or distributors for use in electronic devices. Throughout the production process, manufacturers must maintain strict quality control measures to ensure that the boards meet the required standards for performance and reliability.

In conclusion, the mainstream linear voltage regulator board production process involves several key steps, from design and planning to component sourcing, PCB fabrication, component assembly, testing, and quality control. By following these steps carefully and using high-quality materials and components, manufacturers can produce linear voltage regulator boards that meet the required specifications and provide reliable performance in electronic devices.